Injection Molding Manufacturing

For over 40 years, LECS manufacturing and packaging precision moulded plastic components. Making Plastic Injection Moulding is one of everyday business for us. We specialize in manufacturing of engineering parts, custom plastic injection moulding, and high precision injection molding. With our 30 plus cutting-edge technology injection moulding machines ranging from 40T to 350T, we persistently supplying high-quality plastic and products.

All plastic components manufactured in our facility and are subject to our ISO 9001:2015 quality system which allows us to hold premier plastic injection moulding company in India.

Engineering Plastic Components

LECS has in-house plastic moulding shop for volume production of complex and standard plastic components such as automobile, robotics, electrical, medical and toys.

In addition to our standard range of plastic components, we can manufacture bespoke components to your design, from a straight forward commodity product to complex mouldings. Whether you want 100 parts or a million it’s worth asking if we have the dimensions you need.

LECS Products

| Automotive Components | Machinery Parts |

| Switchgear Parts | Healthcare components |

| Consumer Electronics | Industrial Application |

Plastic Injection Moulding

If you are interested in using plastic moulded component parts for your products, you need to find the right injection molding manufacturer. As an Injection moulding manufacturing company, LECS offers a variety of services, by providing the finest level of quality in their products and customer experiences.

Whether your plastic part is small or large we have the moulding capability to handle it. With shot weights ranging from just 0.5g to 1000g, and component moulding size from 500mm x 500mm maximum, LECS can satisfy all your injection moulding requirements.

Custom Plastic Injection Molding Services

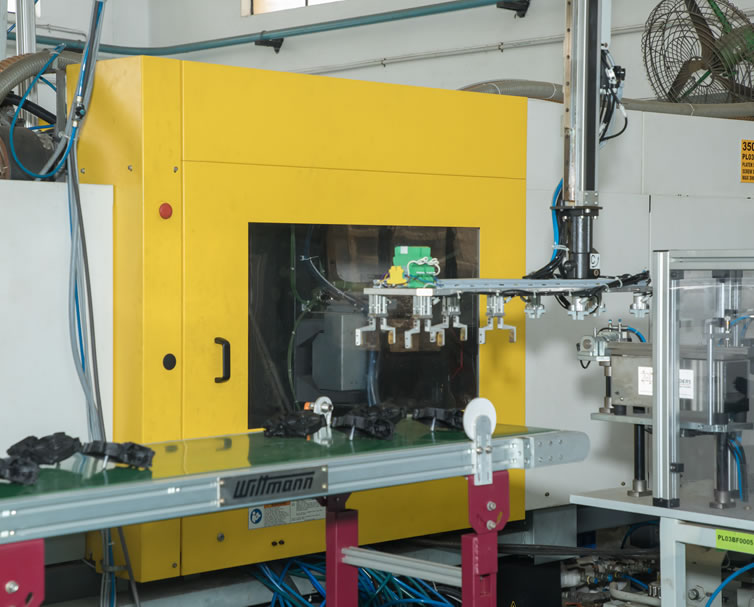

The engineered components which moulded in our plastic machine shop come out with very high quality, precision parts that have very close dimensional tolerances. Also by using the latest high-speed robotic technology, shorter cycle times can be achieved typically reducing take out time to a minimum. This achieves optimum productivity and means we can offer very competitive prices to our customers.

As a professional injection moulding manufacturer, and high-quality custom engineering plastic parts manufacture, we provide comprehensive injection molding solutions to a wide range of industries including prototyping injection moulding and low-high volume injection moulding, Over moulding and Insert Moulding.

We not only offer plastic injection moulding services; we also assemble final products using our in-house produced plastics components – this insight and first-hand experience enable us to provide a high-quality service that meets your individual needs and specification.

Features

- LECS as a full service custom Injection moulding supplier

- Manufacturing Plastic Components weight ranging from 0.5g to 1000g

- Component Size 500mm x 500mm maximum.

- Minimum wall thickness 0.5mm

- Manufacturing High-performance gears and high aesthetic premium consumer electronic parts

- UV stabilized, FR (Flame Retardant), heat stabilized, GF up to 60%, Glass beads up to 50%.

Our Capability in Precision Injection Moulding

- One-stop solution provider for custom Injection moulding

- Horizontal and vertical Moulding Machine

- Over Moulding, Insert Moulding, Valve gate, and hot runner moulding

- Materials ranging from commodity resins to highly engineered resins & thermosets

- High volume, fully automated work cells to low volume prototype run.

- Post moulding operations like pad printing, Ultrasonic welding, coil winding, soldering, barcoding, and assembly operations.

Benefits of Precision Injection Molding

- Efficient production – injection molding is faster than other molding methods, which allows us to produce more parts from a single mold.

- Durability and Accuracy – the use of fillers and other material blends can give plastics strength while reducing cost.

- Complex designs – parts with high levels of detail or complex geometries can be made at high volumes.

- Reduced cost – the use of automation techniques using CNC machine solutions helps reduce labor costs while increasing production efficiency.

Machine Count Chart (Engel, Toshiba & Fanuc Machines)

| Machine Size | 45T to 60T | 80T to 100T | 110T to 150T | 180T to 220T | 250T to 350T |

|---|---|---|---|---|---|

| Quantity | 6 | 11 | 8 | 2 | 3 |

Plastic Raw Materials

| ABS | HDPE | PBT | Phenol formaldehyde | POM |

| ABS-PC Alloy | HIPS | PC | Polyacetals | PP |

| Derlin | PA4/6/Noryl | PEEK | Polyamide (Nylon) 6/66 | Urea Formaldehyde |

Colouring Options

- Natural

- Pre – coloured

- Masterbatch

- Pigment

Certifications

- Integrated Management System, QHSE (Quality, Safety, Health & Environment)

- IATF 16949

- 5s excellency Level

Why LECS

Our facility is equipped with a wide range of modern micro-processor controlled injection moulding machines, many with robotic pick and place automation, assembly automation, cutting edge fully automated measuring machine, supported by ancillary equipment suitable for up-to-date plastic moulding techniques.

You as a customer benefit from swifter tool changes, consistency in the quality and performance of your plastic products and components, and more effective production which in turn results in cost-effective injection moulded plastic components.

Through our In-house plastic moulding shop Custom injection Moulding manufacturing abilities, we keep your project on time, on specification, and on budget. Due to the wide variety of applications and customers that we serve we have experience of processing most injection moulded polymers.